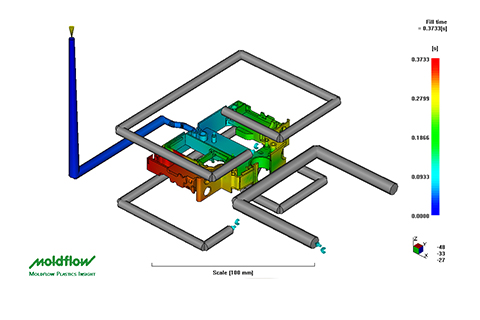

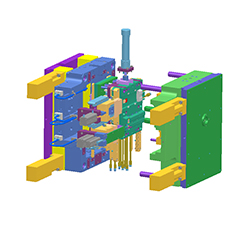

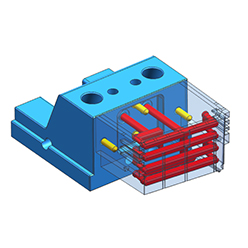

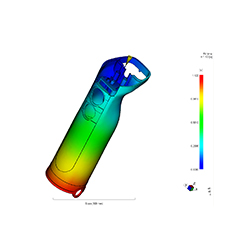

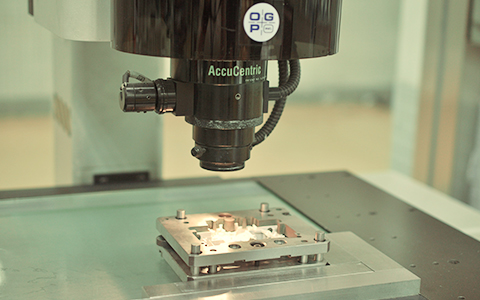

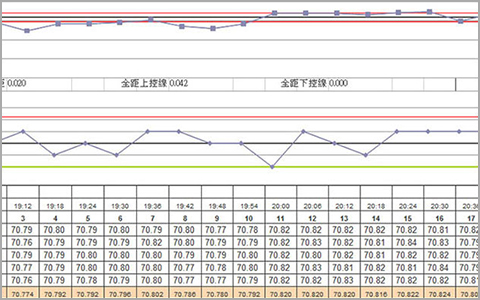

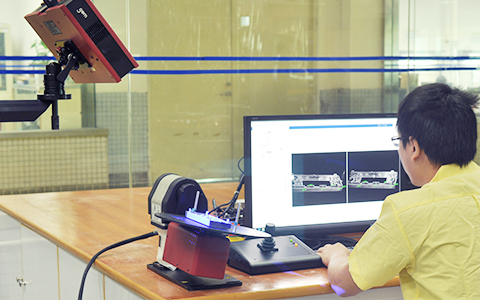

Mold Making

Ultratech specializes in tight tolerance parts,

connector molds, high cavitation molds for

packaging and medical industries.

Ultratech specializes in tight tolerance parts, connector molds, high cavitation molds for packaging and medical industries.